Introduction about Four-Way Radio Shuttle Racking Systems

20 January 2025

With the advancement of modern technology, more businesses are adopting radio shuttle racking systems, intelligent material-handling devices designed to optimize warehouse operations. Traditionally, radio shuttle systems only moved back and forth along tracks, often referred to as two-way or linear radio shuttle racking systems. These systems, while efficient, have limitations in terms of flexibility, particularly when it comes to managing complex logistics and large-scale warehousing.

Two-Way Radio Shuttle

Two-Way Radio Shuttle

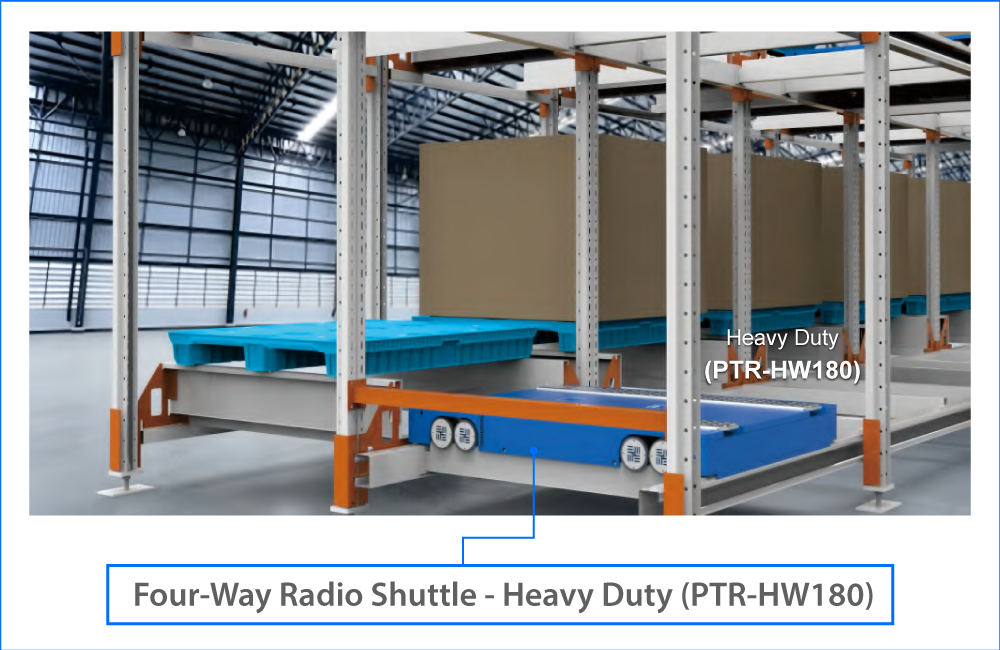

To overcome these limitations, the four-way radio shuttle racking system was developed. Unlike the traditional two-way systems, four-way radio shuttles can move not only forward and backward but also sideways, allowing goods to be transported both vertically and horizontally across intersecting tracks. This added mobility significantly enhances operational efficiency, making the four-way system a more versatile solution for modern warehousing.

The four-way radio shuttle racking system integrates with both a Warehouse Management System (WMS) and a Warehouse Control System (WCS). This integration ensures that goods can be efficiently transported to virtually any racking position, enabling advanced storage, retrieval, and sorting operations. In contrast to traditional automated warehouses, the four-way system provides greater flexibility and precision.

For example, in a traditional multi-level radio shuttle system, if an elevator malfunctions, it could disrupt operations throughout the entire aisle. However, with the four-way radio shuttle system, operations can continue through alternative elevators and connections, minimizing downtime and maintaining system performance. As a result, businesses can see significant improvements in warehouse efficiency and productivity, with output often increasing several times over compared to traditional methods.