Warehouse Racking System

Pallet Flow System

Pallet Flow System

Descriptions:

*Available for Customize

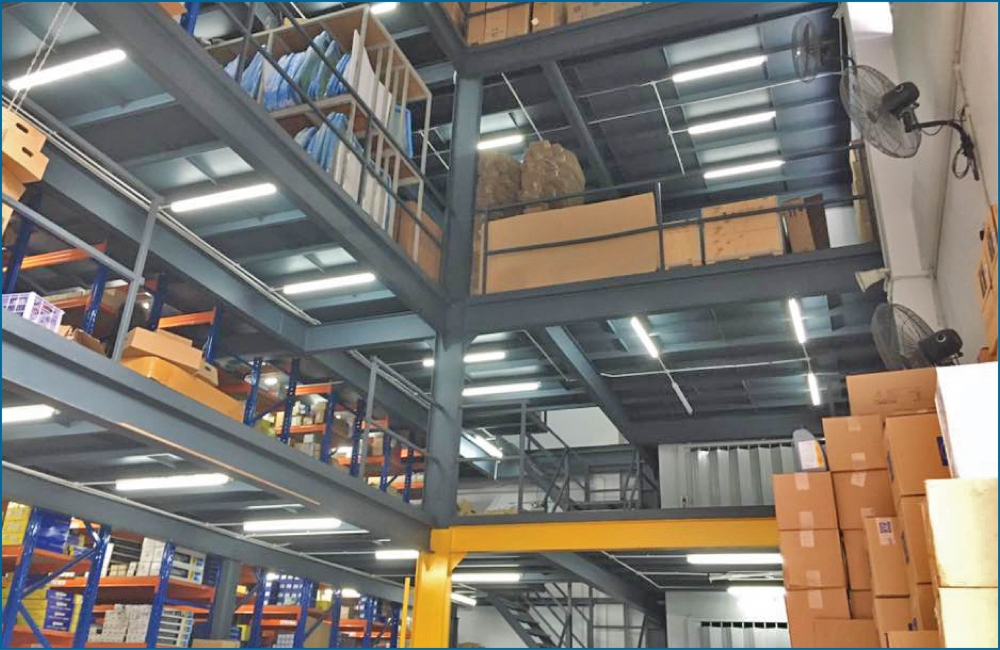

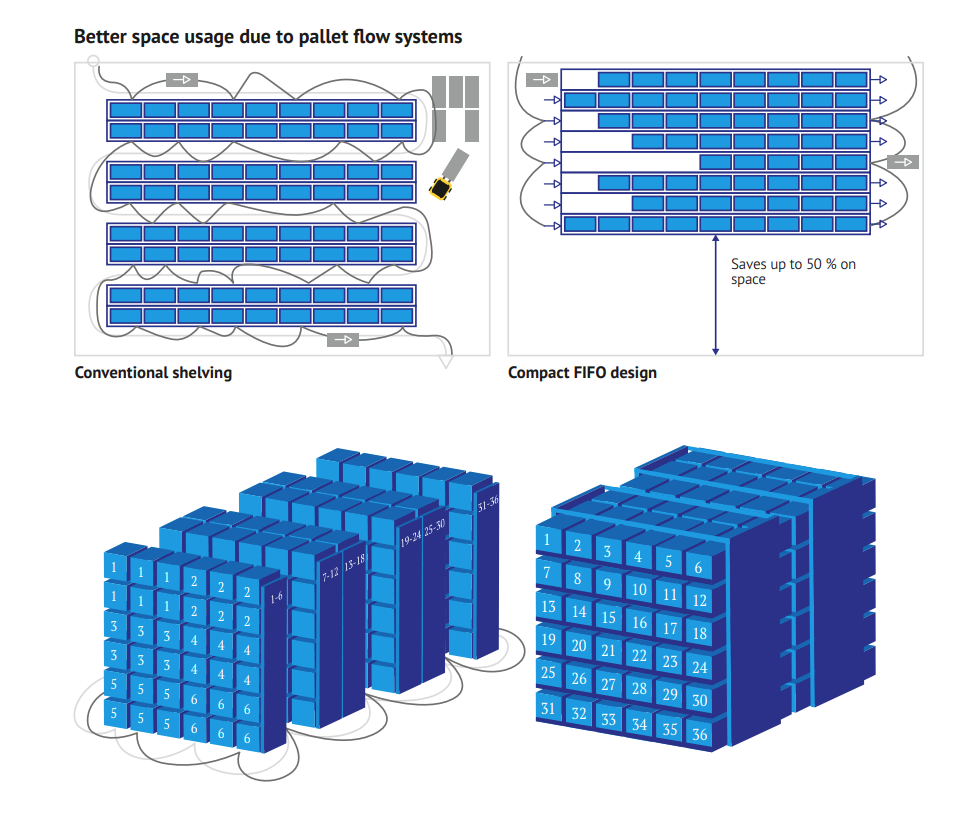

High dense/ dynamic storage

The Pallet Flow Racking System is the perfect choice for businesses operating a First-In, First-Out (FIFO) inventory system. This racking system allows you to save up to 60% of your storage space compared to traditional pallet racking, making it an efficient choice for maximizing warehouse capacity while maintaining streamlined product flow.

It enables seamless inventory rotation and helps reduce errors, making it an excellent solution for industries that prioritize space maximization and operational efficiency.

Image Description:

Key Features:

-

First-In, First-Out (FIFO) System: The Pallet Flow System ensures older inventory is automatically rotated to the front, making it ideal for managing perishable goods or time-sensitive products.

-

Gravity-Powered: Using inclined rails, this system allows pallets to glide from the loading area to the picking area using gravity, reducing the need for forklifts or additional manpower.

-

High Storage Density: By utilizing deep lane storage, the Pallet Flow System can significantly increase the number of pallets stored within the same space, maximizing warehouse capacity.

-

Reduced Handling Time: Since the system automatically moves pallets to the front, your team can focus on picking and packing, reducing overall handling time and improving productivity.

Customizable: Whether you’re working with light or heavy loads, the Pallet Flow System is adaptable to different pallet sizes and weights.

Module:

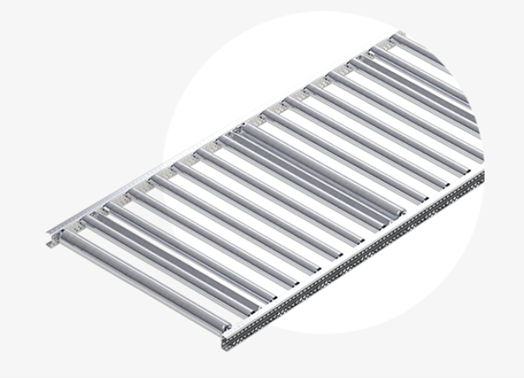

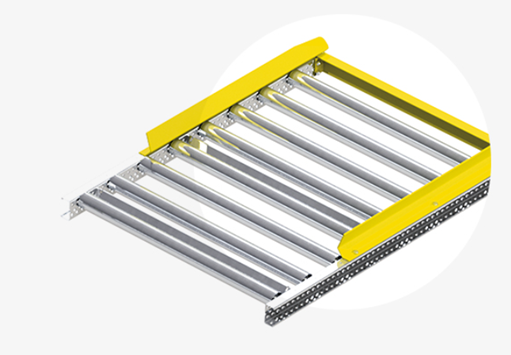

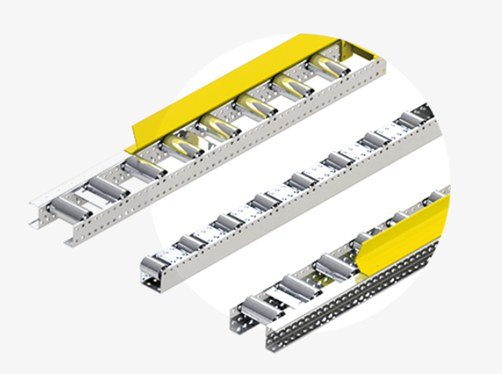

Continuous rollers

Designed for optimal efficiency, our material handling equipment features a tilting mast and automated conveyor loading. To enhance safety for forklift operators, the entry guides are clearly marked with a yellow signal color, ensuring precise positioning. Additionally, roller protection is implemented to prevent damage during daily operations, and in automated systems, reinforced rollers are included for added durability.

The material handling equipment, designed without mast inclination, offers the flexibility of two or three separate roller tracks as an optional feature.