Types of Warehouse Racking: Choosing the Right System for Your Industry Storage Needs

22 February 2025

Types of Warehouse Racking: Choosing the Right System for Your Industry Storage Needs

In modern warehouses, racking systems are the foundation for efficient storage and retrieval of goods. Therefore, choosing the right racking system is essential. It not only optimizes storage space but also streamlines operations, increases productivity, and reduces labor costs. However, with a wide variety of racking systems available on the market, making the right decision is complex. We need to understand all the warehouse racking systems and also consider the industry we are in, the available warehouse space, and the weight of the goods to determine which racking system is best suited for our needs. In this blog, we will explore which racking system is the most suitable for your industry’s storage.

1. TTF Heavy Duty Shelving C/W Mezzanine Floor

Ideal for:

Industries with limited floor space but need for both storage and additional workspace, such as manufacturing and distribution centers.

Features & Function:

-

This 2-in-1 solution combines heavy-duty shelving and a mezzanine floor, offering high vertical storage capacity.

-

It supports multi-tier applications for maximizing space, with an additional floor.

2. TTF Twin Bay Racking System

Ideal for:

Warehouses with a need for maximum space efficiency without compromising load-bearing capacity. Industries like automotive parts, and distribution centers benefit greatly from this system.

Features & Function:

-

The Twin Bay system uses a unique bracing system to double storage capacity while improving warehouse efficiency.

-

This system is designed to handle heavy-duty loads and offers flexibility for storing a variety of goods.

3. TTF Narrow Aisle Racking System

Ideal for:

Warehouses with limited floor space but high storage requirements, especially in industries like pharmaceuticals, and food distribution where maximizing storage density is essential.

Features & Function:

-

The narrow aisle design maximizes storage density by reducing aisle width while still allowing individual pallet access.

-

Special equipment, like combination order pickers or stacker cranes, is used to maneuver through the narrow aisles.

-

The system is designed for high-density storage while maintaining easy access to each pallet.

WEBSITE: LINK

4. TTF Double Deep Racking System

Ideal for:

Industries that require safe, deep storage for pallets, such as warehousing for bulky items, automotive parts, and high-volume goods like furniture or consumer products.

Features & Function:

-

Designed to store 2 or 4 pallets deep within double-entry racks, optimizing space.

-

The system is perfect for warehouses where floor utilization is crucial but easy pallet access is still required.

-

Offers a 50% immediate accessibility rate and aids in stock rotation.

5. TTF Drive-in Racking System

Ideal for:

Industries that store large volumes of similar-sized products, such as food storage, beverage distribution, and automotive parts.

Features & Function:

-

The TTF Drive-In Racking System is designed to maximize storage density by allowing forklift trucks to drive directly into the racking to retrieve pallets.

-

It eliminates the need for cross beams that might block forklift access, providing uninterrupted entry between uprights.

-

The design allows for long-term storage of goods and is well-suited for industries that store large quantities of the same product.

-

Stock rotation is less efficient due to the "Last In, First Out" (LIFO) method.

WEBSITE: LINK

6. TTF Cantilever Racking System

Ideal for:

Storing long, bulky items such as pipes, timber, steel bars, and other materials commonly found in construction, lumber, and steel industries.

Features & Function:

-

TTF Cantilever Racking is designed for the storage of long, heavy items. It can accommodate both single-sided and double-sided loading for easy accessibility.

-

The system allows for quick adjustments in height and width, making it flexible for a variety of goods.

-

A permanent stopper on each arm ensures safe and secure loading and unloading.

WEBSITE: LINK

7. TTF Racking System Mezzanine Floor

Ideal for:

Businesses looking to optimize vertical space for increased storage and operations. Ideal for distribution centers, retail, and manufacturing companies.

Features & Function:

-

The Racking System Mezzanine Floor provides an additional level of storage space, significantly expanding storage capacity without the need for additional floor space.

-

Made from SHS columns and box beam supports, it ensures durability and safety.

-

Easy to install and dismantle without the need for welding, making it an efficient solution for businesses looking to optimize space.

WEBSITE: LINK

8. TTF Truss System Mezzanine Floor

Ideal for:

Businesses looking to maximize vertical space, such as manufacturing facilities, warehouses with seasonal storage needs, and retail distribution centers.

Features & Function:

-

The TTF Truss System Mezzanine Floor is designed with simplicity, safety, and efficiency in mind, providing extra storage or operational space without the need for additional building expansion.

-

Made with SHS columns and a truss-type support beam, it offers sturdy support for large loads and ensures safety.

-

It’s an ideal solution for industries that require more storage capacity but don’t have the budget or space for a complete building expansion.

-

Easy to install and dismantle, without requiring on-site welding, making it a cost-effective and flexible option for businesses.

WEBSITE: LINK

9. TTF Automated Storage & Retrieval System

Ideal for:

High-volume industries that require precision, such as e-commerce, pharmaceuticals, and electronics.

Features & Function:

-

TTF’s AS/RS system integrates with automated stackers, conveyors, and a computer control system for seamless inventory management and retrieval.

-

The system maximizes storage space while improving handling efficiency.

-

It’s ideal for industries where automation and space utilization are critical.

WEBSITE: LINK

10. TTF Steel Platform

Ideal for:

Applications in permanent warehousing, factories, and the place where maximizing vertical space is crucial.

Features & Function:

-

The Steel Platform system is built with a solid universal beam design, ensuring minimal column supports for better space utilization.

-

The top flooring is made of plywood or mild steel plate, ensuring durability.

-

The platform provides additional storage or operational space while adhering to safety regulations.

WEBSITE: LINK

11. Heavy Duty Shelving C/W Boltless Rack

Ideal for:

Industries with high-demand storage and rapid stock movement, such as clothing manufacturers, retail businesses, and warehouses with medium to large-scale inventory.

Features & Function:

-

The combination of heavy-duty shelving and boltless rack is ideal for industries like clothing manufacturing, where quick and easy access to inventory is critical.

-

The top heavy-duty shelving unit holds pallets securely with added safety boards to minimize damage or accidents during storage.

-

The bottom boltless rack ensures fast stock-in and stock-out operations, making it easy to organize inventory for frequent retrieval or updates.

-

The boltless design means no tools are required for assembly or adjustments, which saves both time and labor costs.

WEBSITE: LINK

12. Selective Pallet Racking System

Ideal for:

Industries that need easy, quick access to all pallets, such as food and beverage, retail, and e-commerce.

Features & Function:

-

The Selective Pallet Racking System provides direct access to every pallet in the warehouse, making it ideal for businesses with high product turnover.

-

This system supports a wide range of pallet sizes and weights, and it allows for flexible configuration to optimize space.

-

It ensures efficient stock rotation (FIFO or LIFO), which is essential for inventory management

13. TTF Boltless Rack C/W Top Flooring

Ideal for:

Small to medium-sized storage facilities, such as archives, clothing distribution centers, or businesses with lightweight products and quick access needs.

Features & Function:

-

The TTF Boltless Rack system with top flooring offers quick assembly and is highly stable.

-

It creates another level of storage, maximizing vertical space and saving additional warehouse costs.

-

Ideal for businesses that require flexible, cost-effective storage solutions.

14. TTF Multi-tier Boltless Racking System

Ideal for:

Warehouses and businesses with limited floor space but high vertical space potential. Ideal for industries such as retail, e-commerce, small parts storage, and logistics centers.

Features & Function:

-

The Multi-tier Boltless Racking System offers an efficient way to organize goods in a vertical setup, creating multiple levels of storage.

-

This setup maximizes vertical space and is perfect for warehouses with limited floor space, allowing easy access to inventory across different levels.

-

The boltless design enables quick and easy installation, which makes it ideal for businesses that frequently change their storage needs.

-

Its design provides excellent space efficiency and is perfect for organizing goods, small parts, and bulkier products.

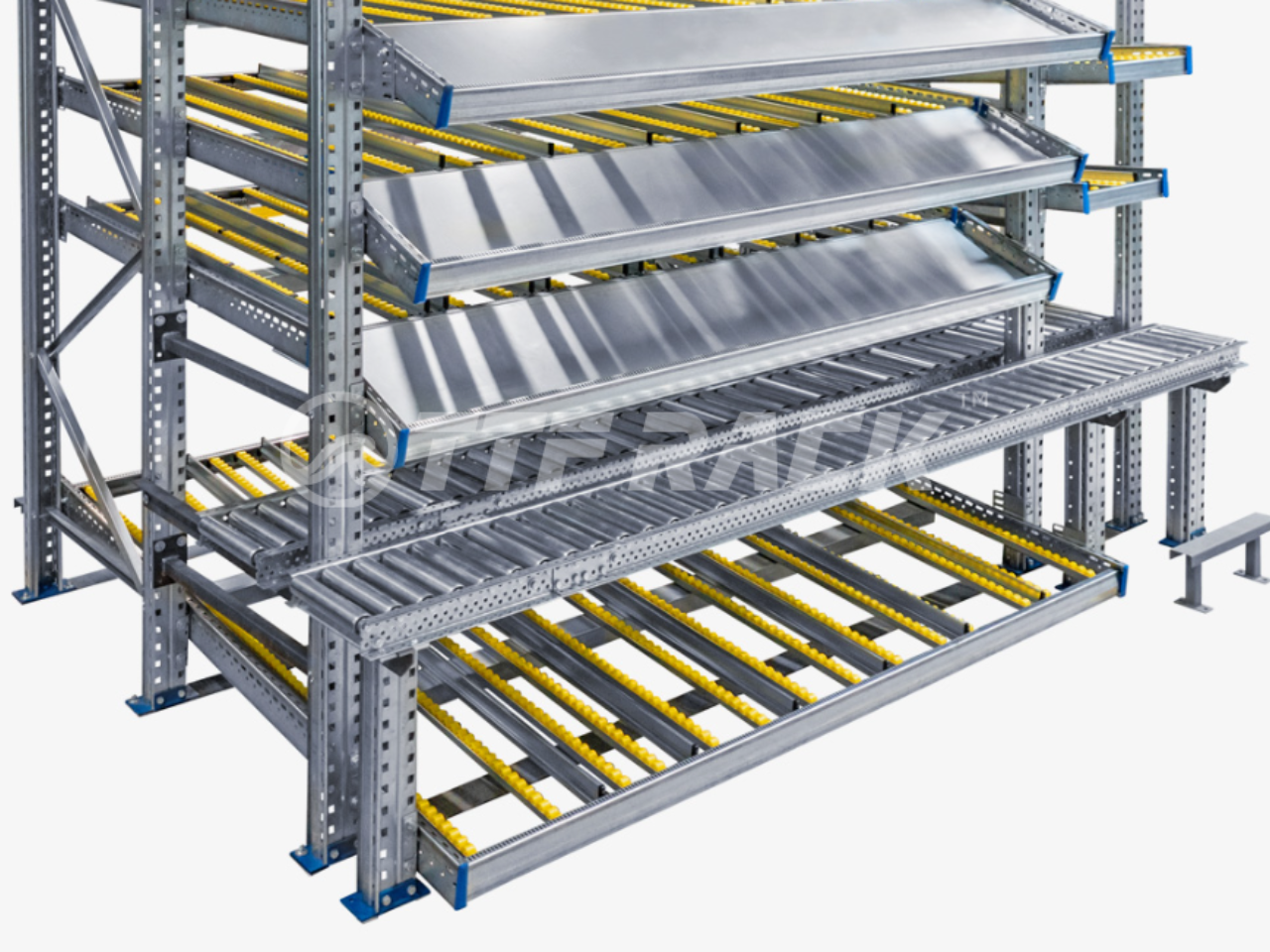

15. Carton Flow System

Ideal for:

Industries that require fast picking speeds and high-density storage, such as retail, food distribution, and e-commerce.

Features & Function:

-

The Carton Flow system uses inclined roller tracks and gravity to move cartons smoothly along the shelving, ensuring efficient order picking.

-

This system enables First-In, First-Out (FIFO) inventory management, making it ideal for industries dealing with perishable goods or time-sensitive products.

WEBSITE: LINK

16. Pallet Flow System

Ideal for:

Industries with high product turnover that require high-density storage and efficient product flow, such as food, beverage, and pharmaceutical sectors.

Features & Function:

-

The Pallet Flow Racking System maximizes storage density while ensuring the automatic rotation of inventory (FIFO).

-

Using gravity-powered inclined rails, pallets glide from the loading area to the picking area, minimizing forklift traffic and improving operational efficiency.

WEBSITE: LINK